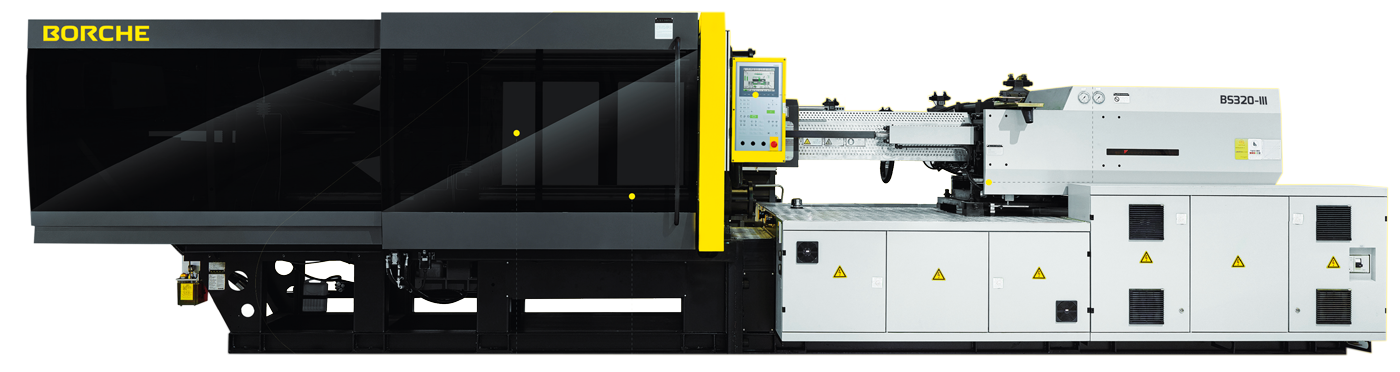

One machine realises diverse demands

BS-Ill Servo Series are featured with adequate power system, high-precision control, stable performance, high versatility and three sizes of screw barrel, which satisfies different production requirement.

High Platen Stiffness

European standard platen with higher platen stiffness, good for production requiring high strength, high load and high precision.

Keba Controller

Keba controller, Stable and durable

Linear Guide

Linear guide, smooth and fast

Energy Saving Servo

Energy saving servo motor with A level pump, Efficient and low running cost

Advanced technique realises high efficiency and energy saving demands

BS-Ill Servo Series adopt multi-pump control system, which cooperating with CAN BUS and running flexibly with real-time production demands, can produce small size plastic parts with a single pump and produce big size plastic parts with multi-pump. Lower energy consumption as well as higher-efficient productivity provides a competent and economical solution to satisfy customer requirements.

BS-Ill Servo Series are accredited as National First Grade Energy Saving and the best application only reach 60% of first grade consumption level. Compared with traditional hydraulic system, BS-Ill Servo Series can save 20%-80% energy. Servo motor proportionally delivers hydraulic oil based on actual needs, avoiding extra heating and temperature rise, ensures water saving.