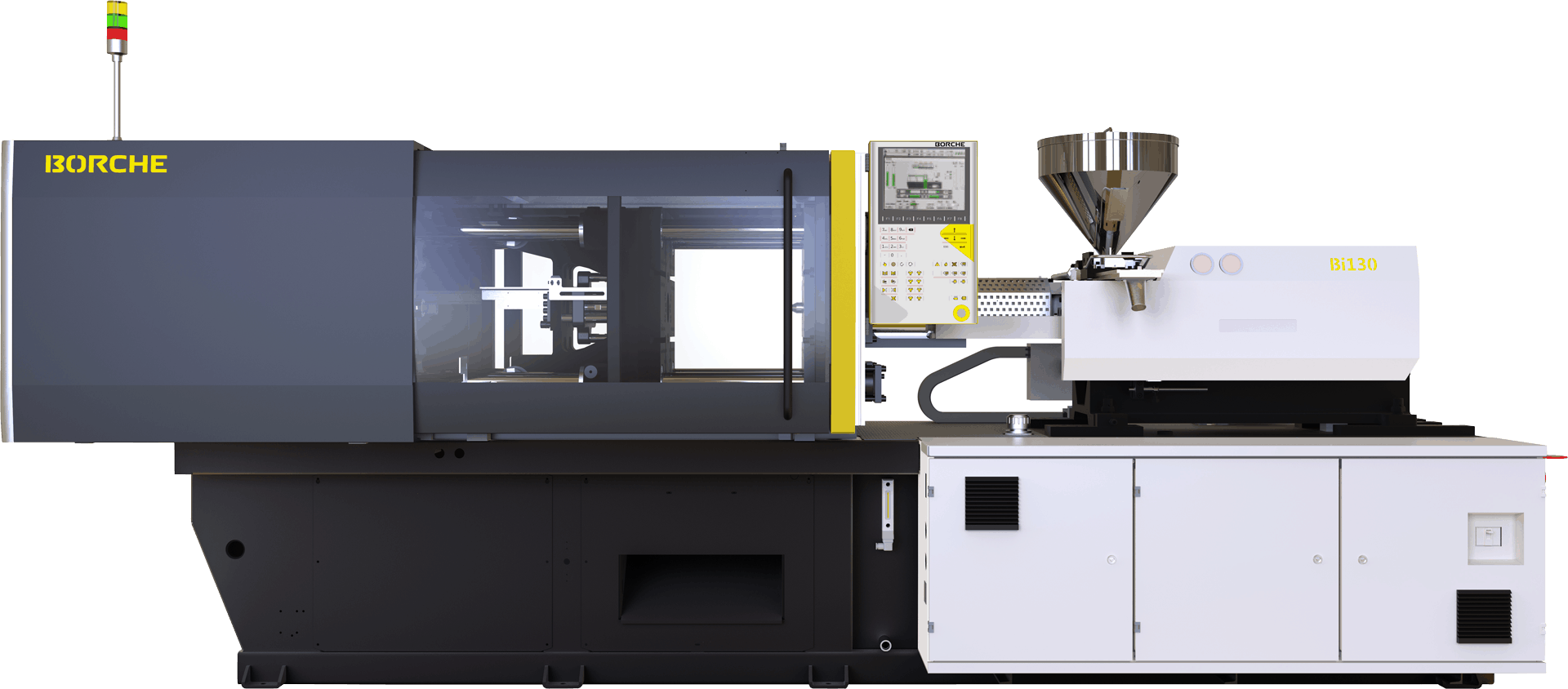

Bi Series

Bi series is able to connect peripheral equipment and realize two-way data communication, which intergrates the information of the peripheral equipment into the machines controller. Bi series can be linked with PC or mobile phone. User can easily monitor the status of the machines through the interconnectibility and its sensors inbuilt.

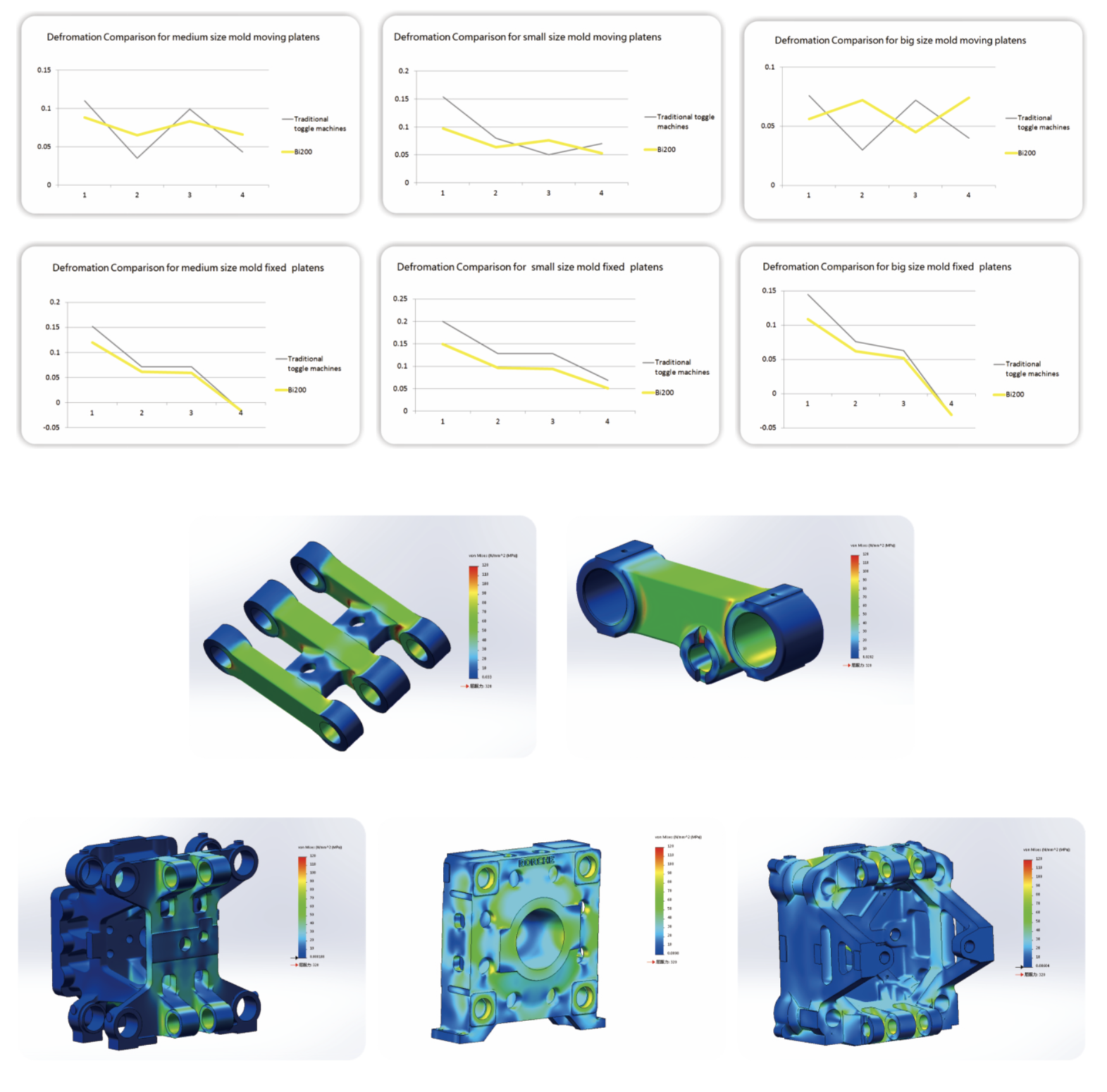

Optimized Toggle System

Optimized toggle system for longer opening stroke and faster dry cycle

Enhanced and Increased platen

Enhanced and Increased platen, stronger and adaptable for bigger mold

Enhanced frame

Enhanced frame for better strength

More Sensors

More sensors adapted and connection module inbuilt for connectibility

Stable and durable Keba controller

Keba controller interconnected with auxiliary equipment(limited brand)

Organized cabinet

Organized cabinet, seperated high/low volt cabinet for safer operation

Enlarged power system

Enlarged power system with servo motor, fast and efficient

Linear Guide

Linear guide, fast and smooth

Organized pipe fixing

Organized pipe fixing, tidy

Modular design

Modular design, 3 inj. Units (9 screws) available for same clamping size, wider application

Interconnected - Stable - Precise

The machine is equipped with a different interface for data collection and communication, uploading machine real status, technical parameters and status of peripheral equipment to PlasCloud platform.